Safety Power is a global innovator in SCR design.

We have extensive in house engineering capabilities, work with leading educational institutes and have a considerable installed base.

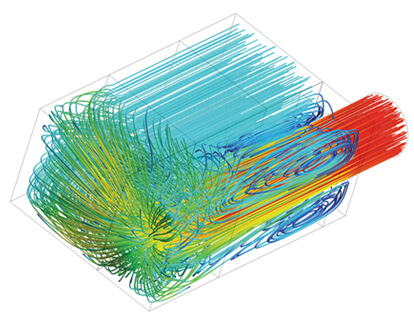

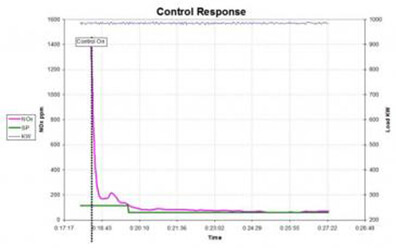

All our systems have highly optimized controls, injection and mixing capabilities.

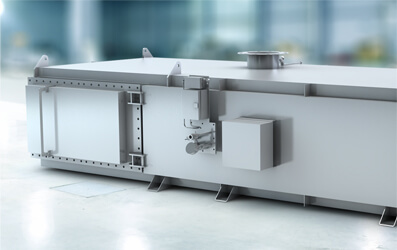

Highly optimized designs ensure industry leading Selective Catalytic Reduction (SCR) system performance in a highly compact footprint. Optional Oxidation Catalyst, Diesel Particulate Filter and Silencing can all be integrated into the ecoCUBE® housing.

The compact design allow easy integration into your Natural Gas or Diesel generating plant. In addition the design provides a very low system back pressure making it suitable for most engines.

Click here to download Engineering Specification.

Click here to download our ecoCUBE brochure.

Click here to download our Data Center brochure.

Safety Power is a ISO 9001 registered company. All of our welders are certified and all of our reactors are pressure tested. In addition each reactor goes through extensive testing and extensive quality control checks.

All reactors our standard ecoCUBE® are constructed from stainless steel and can be factory insulated.

Click here to see our How It's Made Video.

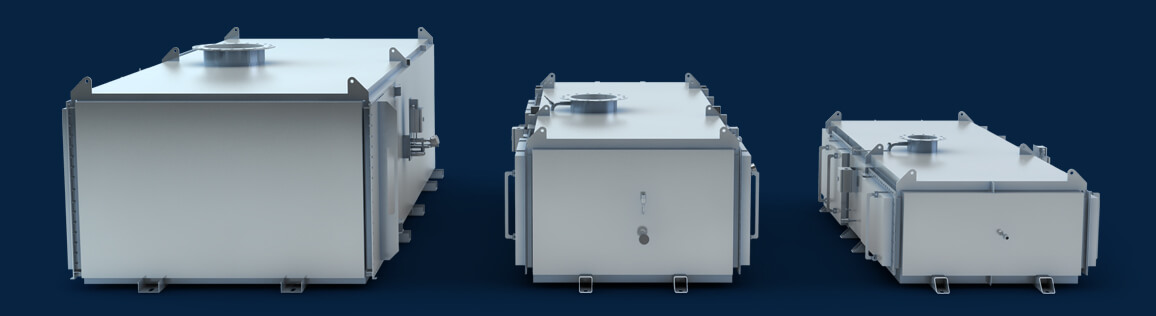

The optimized ecoCUBE® designs are suitable for engines ranging from 500kw to 5 MW. The ecoCUBE® family has a large installed base that has been extensively tested by 3rd party compliance firms.

Safety Power’s unique design makes onsite installation easy.

All catalyst and sensors are installed at our factory so that the system is ready to go when it arrives.

In addition lifting lugs are provided for easy hoisting using a crane or fork lift. Please see the video below which outlines the installation process.

The ecoCUBE(R) is able to achieve the most stringent Emissions Regulations and is compliant with MOE 0102463, US EPA Tier 4F, US BACT Natural Gas Limits and Euro Emissions Levels.

We have several installations that deliver sub 5 ppmvd NOx levels. Below is a video of a recent CHP project that we completed.

With over 500 installations worldwide the ecoCUBE® has been proven and tested for many applications. The flexible and compact design is ideal for

Click here to download our Applications brochure.

Click here to download our Data Center brochure.

The highly compact ecoCUBE® Low Profile (LP) reactor is approximately 30% smaller than our standard ecoCUBE® emissions system. The ecoCUBE® LP is built upon our well proven ecoCUBE® product that has been successfully deployed in hundreds of installations for over 10 years.

The ecoCUBE® LP incorporates our most advanced level of mixing; yielding a high degree of NOx reduction into a reactor housing that has a height of ~30”(0.77m).This low profile design, allows for installations in very tight spaces or where customers hope to visually blend this equipment into their existing infrastructure.

Safety Power’s ecoCUBE® LP can be configured to reduce NOx, CO & HC while also attenuating exhaust noise. The design is easily serviceable with access to the SCR catalysts and front & back access to all sensor components. The ecoCUBE® LP has been designed specifically for Diesel engine applications.